Polyolefins купить от 22,00 руб.

Polyolefins: The Next Generation of Sustainable Materials

Polyolefins are a class of synthetic polymers derived from the polymerization of olefins, primarily ethylene and propylene. They have become ubiquitous in modern society, spanning a wide range of applications including packaging, films, fibers, and even high-performance materials. In this article, we'll explore the key characteristics of polyolefins and how they contribute to their widespread use.

1. Sturdy and Durable: Polyolefin materials are characterized by their high strength and rigidity, making them ideal for structural applications such as building siding, transportation components, and industrial equipment.

2. Recyclability: Polyolefins can be easily recycled, reducing the amount of waste sent to landfills and making them a sustainable choice for manufacturers.

3. Low-Cost Processing: Polyolefin manufacturing processes are relatively inexpensive compared to other commodity polymers. This makes polyolefins a cost-effective option for many applications.

4. Performance Flexibility: Depending on the type of polyolefin used, it can exhibit varied properties and performance characteristics. For example, linear low-density polyethylene (LLDPE) is used in food packaging due to its excellent barrier properties, while polypropylene (PP) is known for its strength and heat resistance.

5. Alkyl Phenol Alkyl Amine (APA): The addition of APA to polyolefin formulations improves the flame retardancy and smoke suppression performance of the material. This additive has been widely adopted in the automotive industry for interior panels and exterior parts.

6. Bio-Based Polyolefins (BBPOs): Recently, there has been a growing interest in bio-based polyolefins that are produced from renewable sources such as corn, hemp, or sugarcane. These materials offer the promise of lower carbon footprints and reduced environmental impact.

In conclusion, polyolefins continue to play a significant role in our modern world, providing a diverse range of benefits from strength and durability to sustainability and recyclability. As technology continues to advance, the potential for polyolefins to contribute to a more circular economy becomes ever more promising.

Polyolefins are a class of synthetic polymers derived from the polymerization of olefins, primarily ethylene and propylene. They have become ubiquitous in modern society, spanning a wide range of applications including packaging, films, fibers, and even high-performance materials. In this article, we'll explore the key characteristics of polyolefins and how they contribute to their widespread use.

1. Sturdy and Durable: Polyolefin materials are characterized by their high strength and rigidity, making them ideal for structural applications such as building siding, transportation components, and industrial equipment.

2. Recyclability: Polyolefins can be easily recycled, reducing the amount of waste sent to landfills and making them a sustainable choice for manufacturers.

3. Low-Cost Processing: Polyolefin manufacturing processes are relatively inexpensive compared to other commodity polymers. This makes polyolefins a cost-effective option for many applications.

4. Performance Flexibility: Depending on the type of polyolefin used, it can exhibit varied properties and performance characteristics. For example, linear low-density polyethylene (LLDPE) is used in food packaging due to its excellent barrier properties, while polypropylene (PP) is known for its strength and heat resistance.

5. Alkyl Phenol Alkyl Amine (APA): The addition of APA to polyolefin formulations improves the flame retardancy and smoke suppression performance of the material. This additive has been widely adopted in the automotive industry for interior panels and exterior parts.

6. Bio-Based Polyolefins (BBPOs): Recently, there has been a growing interest in bio-based polyolefins that are produced from renewable sources such as corn, hemp, or sugarcane. These materials offer the promise of lower carbon footprints and reduced environmental impact.

In conclusion, polyolefins continue to play a significant role in our modern world, providing a diverse range of benefits from strength and durability to sustainability and recyclability. As technology continues to advance, the potential for polyolefins to contribute to a more circular economy becomes ever more promising.

Каталог Polyolefins (polyolefin basell alkyl phenol amine)

Цена: 5120 Руб. 49.33$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цены актуальны на 2025-07-05 11:16:17

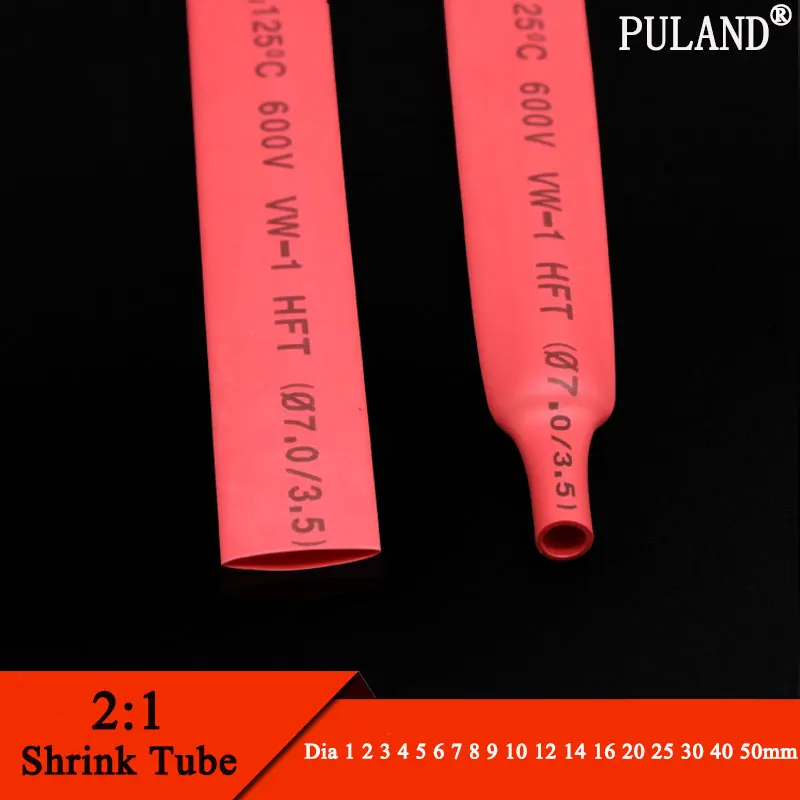

Цена: 85 Руб. 1.08$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 79 Руб. 1.01$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 37 Руб. 0.47$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 43 Руб. 0.56$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 40 Руб. 0.43$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 62 Руб. 0.79$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 804 Руб. 10.2$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 530 Руб. 6.73$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цены актуальны на 2025-07-05 11:16:17

Цена: 46 Руб. 0.49$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цены актуальны на 2025-07-05 11:16:17

Цена: 22 Руб. 0.29$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 38 Руб. 0.49$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цена: 40 Руб. 0.43$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цены актуальны на 2025-07-05 11:16:17

Цена: 43 Руб. 0.55$

Бесплатная доставка

Цены актуальны на 2025-07-05 11:16:17

Цены актуальны на 2025-07-05 11:16:17