Welding technology купить от 117,00 руб.

Welding technology is an important part of manufacturing industries. It's used to join metal together in order to make stronger and more durable structures.

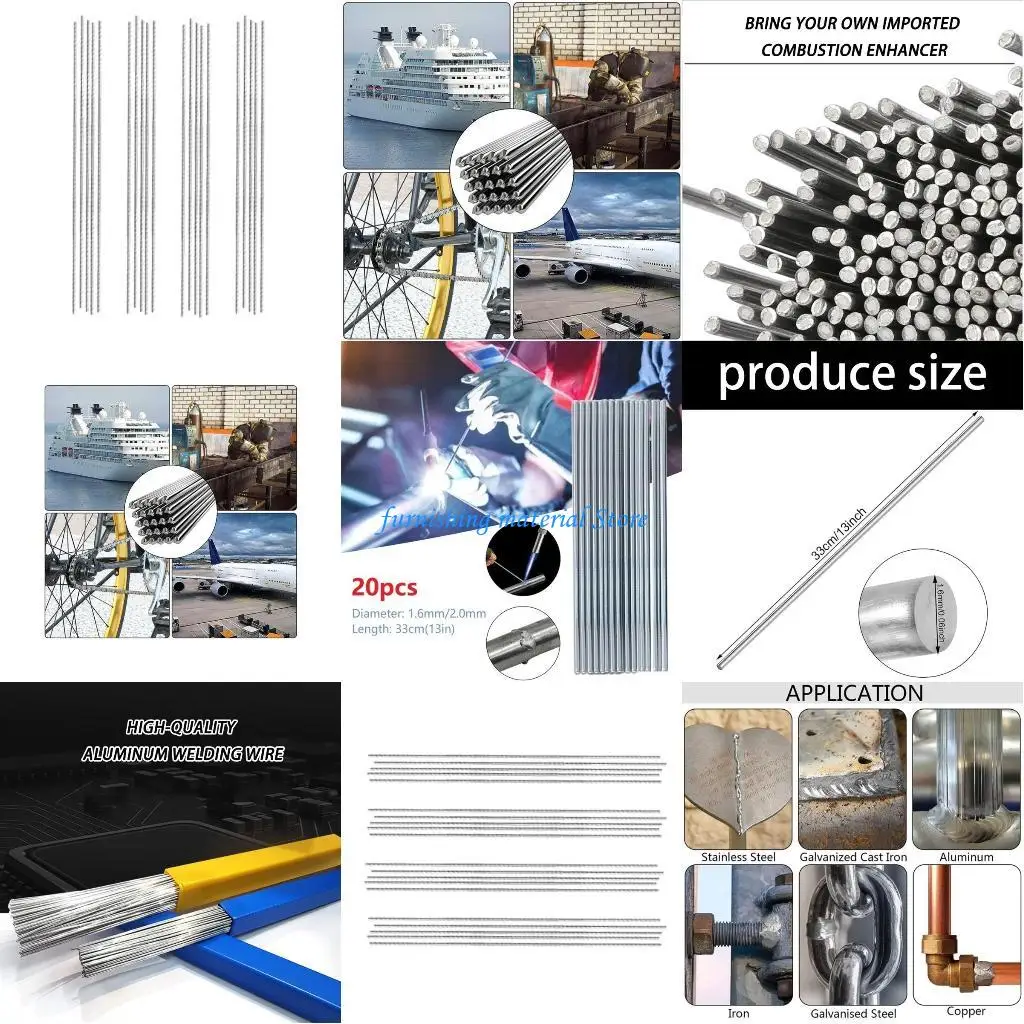

The main methods of joining metal parts include welding, brazing, and soldering. The most common method of joining is welding, which involves heating the parts to be joined until they melt, then allowing them to cool and solidify while still joined together. This creates a strong bond between the two pieces of metal.

There are many types of welding, each with its own advantages and disadvantages. Gas metal arc welding (GMAW) is one of the most common types of welding. It uses a continuous current arc to melt the metal being welded. This type of welding is often used for joining steel or aluminum.

Another type of welding that is used is shielded metal arc welding (SMAW). This type of welding uses a consumable electrode that supplies both flux and metal to the welding arc. SMAW is often used to weld steel.

In addition to the above methods, there are also other welding techniques such as flux-cored arc welding (FCAW), tungsten inert gas welding (TIG), submerged arc welding (SAW), and resistance welding (RW).

Welding is a process that requires skill and knowledge. Welding technicians need to be trained and certified in order to perform this job. Welders must have a good understanding of the physics behind welding and how to use various welding machines and equipment. They also need to know how to read diagrams and blueprints that show the welding joints and how they should be done.

Welders also have to be able to work in a safe manner. They need to wear personal protective equipment such as safety goggles, leather gloves, and fireproof overalls. They also have to follow safety rules and regulations that are set by the government and industry standards.

The main methods of joining metal parts include welding, brazing, and soldering. The most common method of joining is welding, which involves heating the parts to be joined until they melt, then allowing them to cool and solidify while still joined together. This creates a strong bond between the two pieces of metal.

There are many types of welding, each with its own advantages and disadvantages. Gas metal arc welding (GMAW) is one of the most common types of welding. It uses a continuous current arc to melt the metal being welded. This type of welding is often used for joining steel or aluminum.

Another type of welding that is used is shielded metal arc welding (SMAW). This type of welding uses a consumable electrode that supplies both flux and metal to the welding arc. SMAW is often used to weld steel.

In addition to the above methods, there are also other welding techniques such as flux-cored arc welding (FCAW), tungsten inert gas welding (TIG), submerged arc welding (SAW), and resistance welding (RW).

Welding is a process that requires skill and knowledge. Welding technicians need to be trained and certified in order to perform this job. Welders must have a good understanding of the physics behind welding and how to use various welding machines and equipment. They also need to know how to read diagrams and blueprints that show the welding joints and how they should be done.

Welders also have to be able to work in a safe manner. They need to wear personal protective equipment such as safety goggles, leather gloves, and fireproof overalls. They also have to follow safety rules and regulations that are set by the government and industry standards.

Каталог Welding technology (технология, сварки, пистолет, сварочный)

Цена: 1688 Руб. 20.86$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 1390330 Руб. 17176.3$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 815 Руб. 10.07$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 1159 Руб. 12$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 313 Руб. 3.87$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 20164 Руб. 249.11$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 2127 Руб. 21.4$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цены актуальны на 2025-11-20 15:21:46

Цена: 2085 Руб. 25.76$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 6856 Руб. 84.7$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 16042 Руб. 180$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 637 Руб. 7.88$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 214 Руб. 2.23$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 195 Руб. 2.42$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 14600 Руб. 180.37$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 297 Руб. 3.67$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 117 Руб. 1.45$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 557323 Руб. 6885.23$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46

Цена: 10514 Руб. 129.9$

Бесплатная доставка

Цены актуальны на 2025-11-20 15:21:46